+86 15633683072

| Positional Repeatability | 0.08mm |

| Drive Capacity | 2600w |

| Rated Duty Cycle | 60% |

| Rated Voltage | 380V |

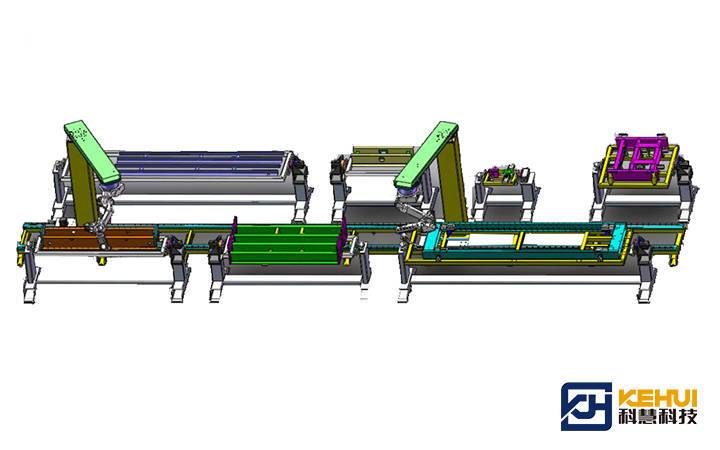

| Welding Station | Economical, divided into automatic flip and fixed welding |

| Workpiece Dimension | Can be customized according to the actual needs of customers |

| Single station workpiece weight limit | 500kg |

| Maximum carrying weight | Can be customized according to the actual needs of customers |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com